Shipment Zanghzouh (China) to Balboa (Panama)

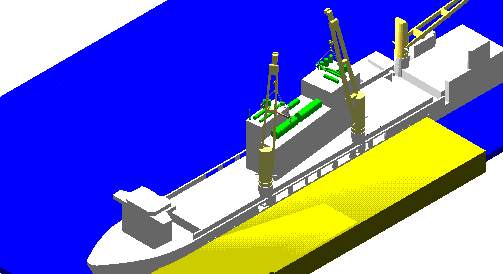

A world wide growing container market, new terminals and harbours need new on shore equipment like RTG`s. Starting more or less in 2000 SAL fleet nowadays the leading carrier to transport RTG`s for handling containers at shore side.

RTG`s produced by Kalmar or ZPNC, but also by Noell and Regiane will be shipped world wide on deck of heavy lift vessels.

Lashing and securing requirements, designed by Gottwald Engineering, today is the standard requirement in all tender documents of the leading manufacturers.

A very close cooperation with Noell China design department enabled in 2006 a new transport design. Fully errected RTG`s with reduced span allows today the transport of 8 RTG`s on deck instead of 4 which was the former limit. In 2006 5 transports with this stowage idea were utilized successfully.

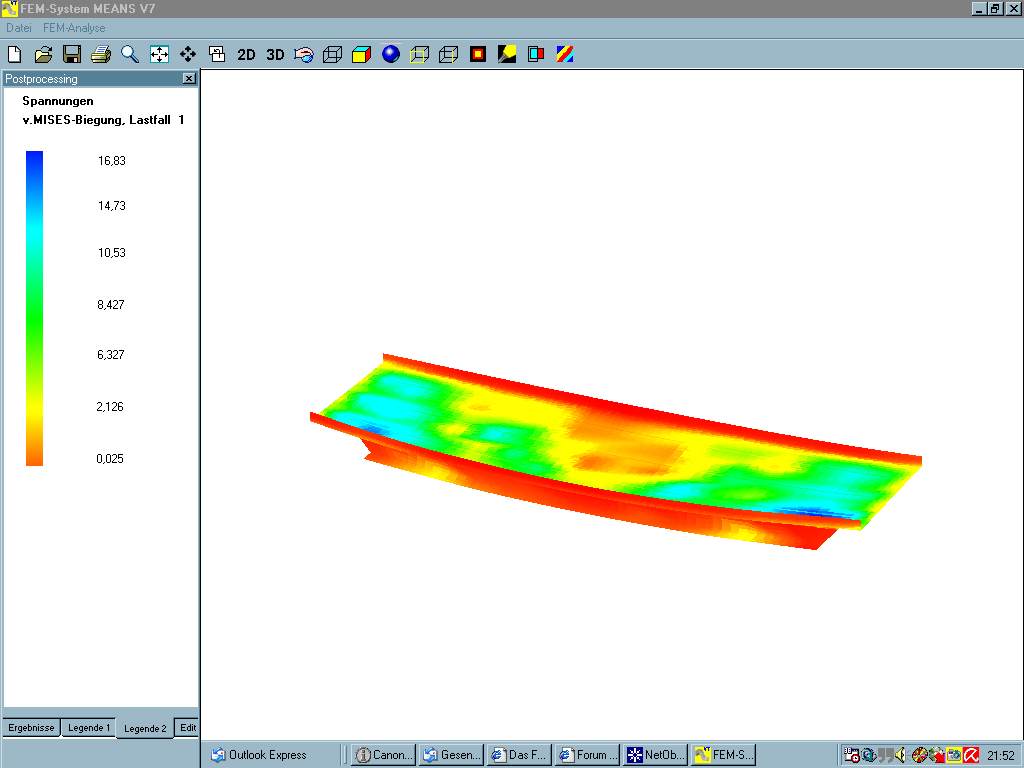

FEM-calculation of the bridge.

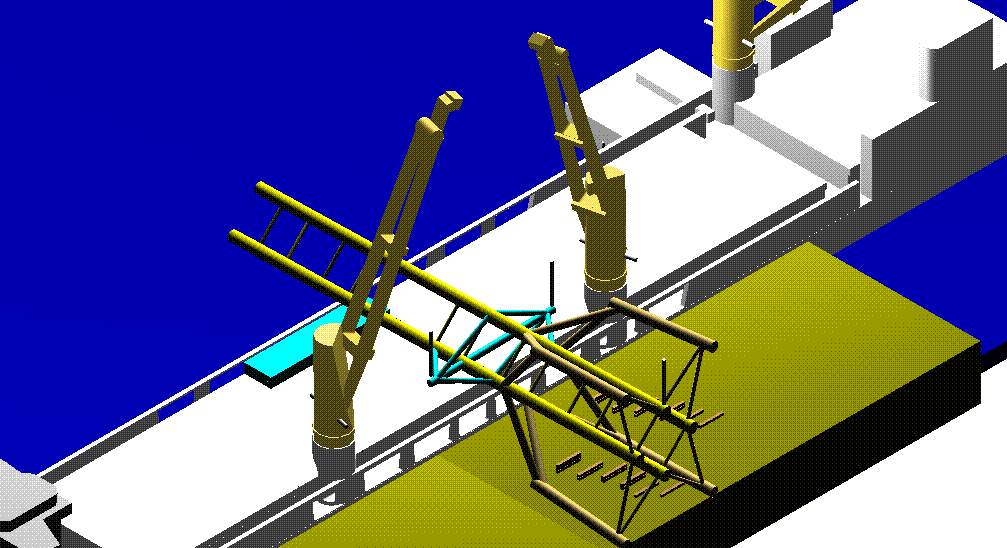

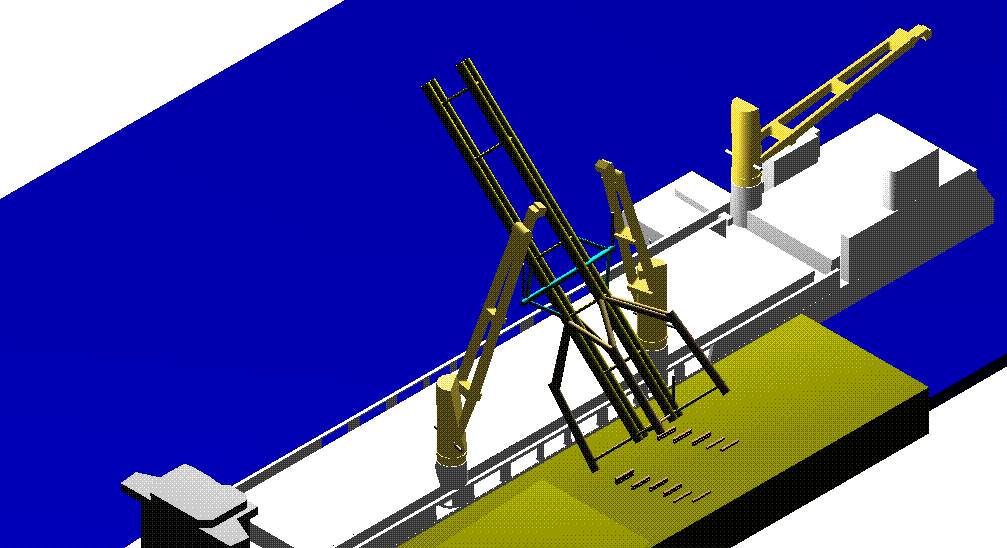

Bridge hatch - poopdeck designed by Gottwald Engineering

Bridge hatch - poopdeck designed by Gottwald Engineering

Pohukura Project

Loading in Australia.

Pohukura`s joint venture owners, Shell, Todd, and OMV will start as soon as possible commercial gas production at Pohukura (New Zealand) offshore gas field.

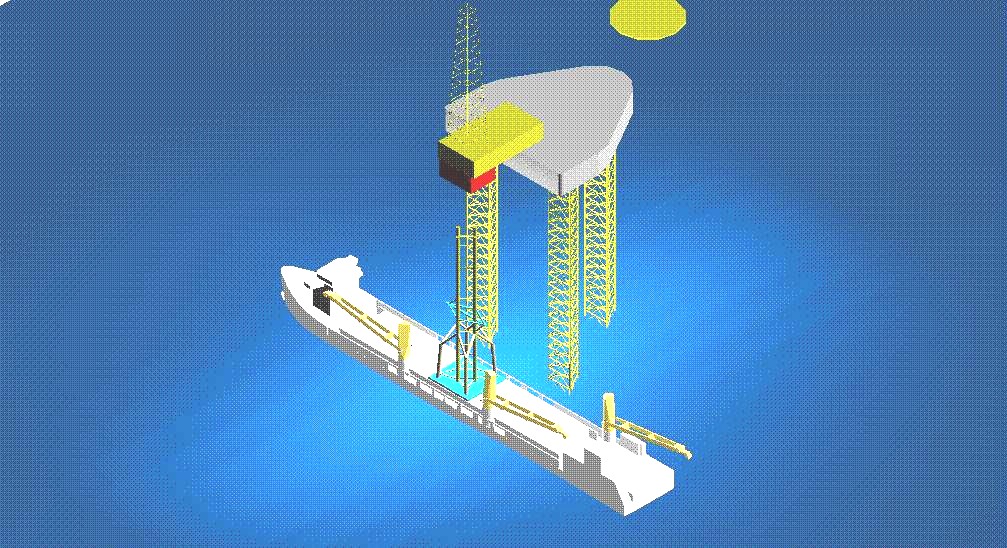

2005/2006 a transport concept for a 420 ton steel jacket plus topside platform was designed and produced in cooperation with Lühe engineering, German Lloyd and MARIN Maritime Research Institute in Netherlands. 3D modelling of lifting jacket, upending (turning of 90°) as well as basic analyse of seastage conditions were carried out by Gottwald engineering.

3D evaluation of loadout and discharging.

Loading.

Biodiesel Module

Just in time and complete delivery to reduce installation costs.

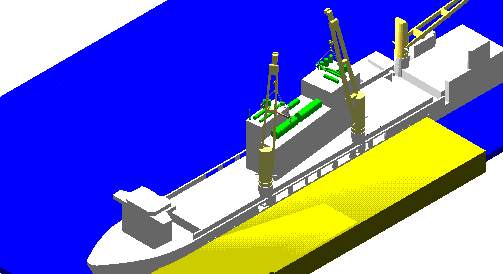

The Biodiesel Module, designed by Lurgi, manufactured in Henderson (Australia), was transported on MV Wiebke (SAL). Two problems had to been solved: -the lifting height and the foundation for seatransport, due to the fact that in the original plan the 320 ton module had only point loads onto the deck. Some parts had to be dismounted on top of the module to ensure swinging in the module by the two portside ship cranes. This was checked by 3D clash test.

An additional framing system had to be designed and mounted to ensure the weight distribution on deck.

This module can be an example for a couple of refinery modules transported in the past like Ormen Lange Project (Norsk Hydro), Melkoya Project (Statoil), Janmargar (Reliance) etc.

3D evaluation of loadout and discharging.